Leslie Mateo

How did you get to where you are today? What was your training or education?

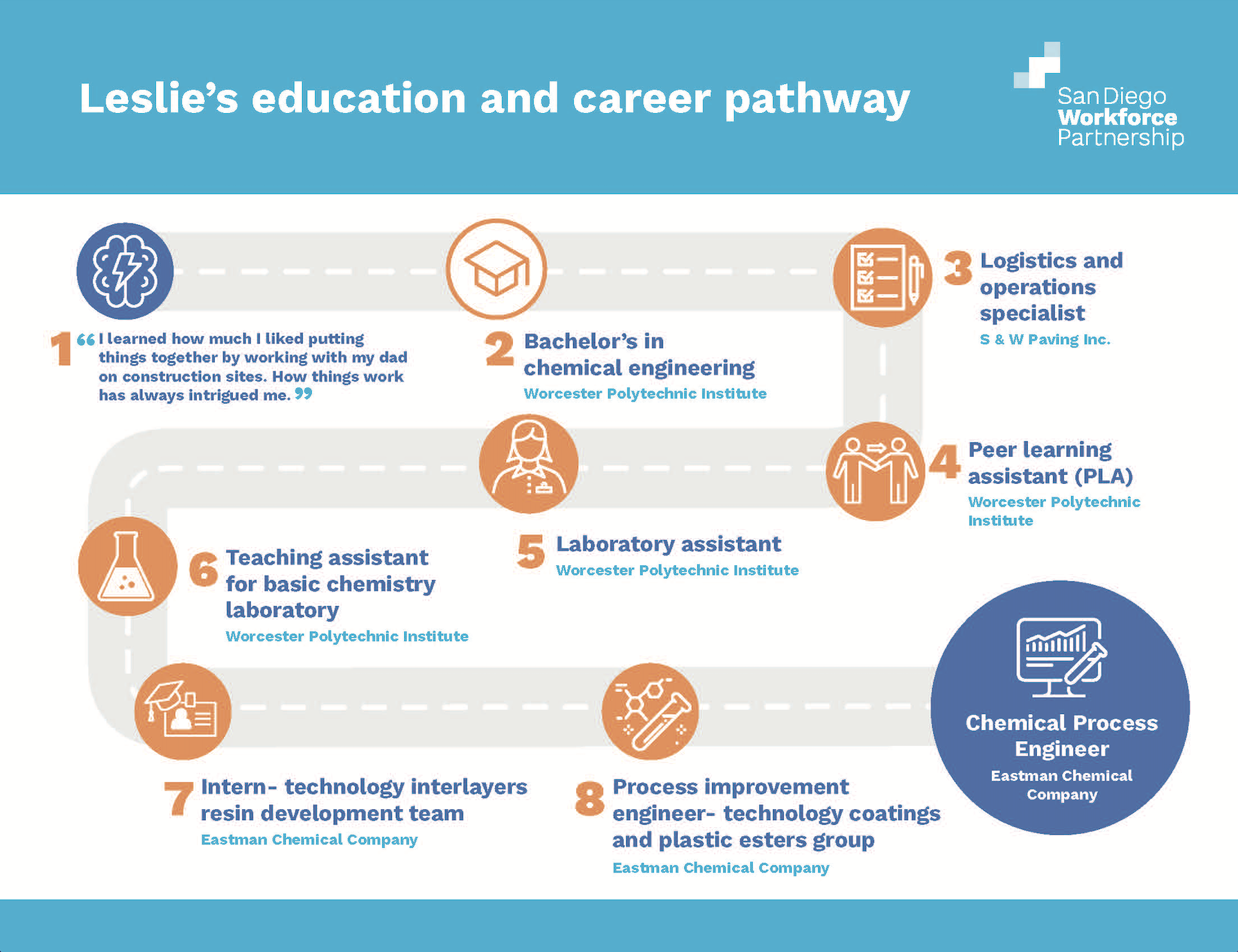

Growing up, my mom was a school bus driver and my dad had a paving business and worked in construction. My dad used to take me on jobs with him on the weekends and I really enjoyed being a hands-on worker. In school, I was always really interested in math and science because I was curious about how things worked. I enjoyed how logical math can be and figuring out the answer to problems one step at a time. When I learned about engineering, I made the connection that it’s a lot like both math and what I did with my dad in construction. I thought about it like putting the building blocks together to create something that’s either new or improved.

I took my first chemistry class during my sophomore year of high school. It was really hard but I challenged myself. At the end of the semester, I was really proud of myself, how hard I worked and how much I learned. I wanted to continue that passion of being a lifelong learner. In college, I decided to be a chemical engineer and earned my bachelor’s degree from Worcester Polytechnic Institute in Massachusetts. Now I work as a chemical engineer and it’s a career where I get to be hands-on and combine my two favorite high school subjects: chemistry and math.

Describe your job.

I work as a chemical engineer at a plant that produces all different types of chemicals that end up in things you would use every day. For example, we produce plastics that are used to make water bottles, televisions and even fabric. We’re also developing new technologies that take recycled materials and make them into new products.

My job within the plant is to design solutions for anything that breaks. There is a lot of different machinery that makes up a chemical plant, like heat exchangers and distillation columns. If one of them stops working, I replicate the existing design to understand the issue and create a better design to solve the issue. Sometimes the machinery just needs a different type of metal while other times it needs a complete redesign. It’s a lot of fun to use different design techniques and programs to work on different problems.

More than just solving the problem in front me, I also strive to find other ways to make things work better. I take the initiative to go the extra step and create a design that’s even more efficient than what they’re even looking for. This way, the machinery can last ten, twenty or even thirty years without any issues.

What are the most important skills you use in your work?

Communication is really important. To me, this means both communicating my thoughts and ideas and listening intently to the subject matter experts, some of whom have been working at the plant for longer than I’ve been alive. Attention to details is another important skill. Because my role is very technical, the slightest little things can change the design and function of what will be built. Paying attention to all the details can save me a lot of time.

What is something you find challenging about your job?

In my job, no two problems look exactly the same. I work across a massive chemical plant that employs about 11,000 people running a bunch of different processes, so I start from the beginning for every project. Often, the actual equipment I need to work on is different from the diagrams that we have on file. It’s important for me to start with modeling what is actually in the field with the current conditions. This usually takes about a week of back and forth with the person in charge of the process. Once I have the unit modeled with the current conditions, I can start designing it with the new specifications. For example, if they need to make a change to the temperature of a chemical, I might suggest making the heat exchanger bigger or smaller, or adding more tubes into the inside of the equipment. I work on the solutions, testing each one along the way, and present them to the person in charge of the process. Once this person has validated the final solution design, I send the design to our vendors to produce the end product.

What do you love most about your job?

I love that I get exposure to all different types of plant processes. I’ve gotten to go inside a distillation column, which are towers that can be about 15 feet tall or other sizes depending on the process. We geared up and climbed up the tower to check the internals and perform an inspection. Experiences like this keep my job interesting. Getting exposed to what things look like in the real world also helps me a lot when I am modeling different pieces of equipment on the computer. I also love interacting with all different types of individuals from different work backgrounds, like mechanical engineers, operators and maintenance coordinators.

What advice would you give young students thinking about pursuing engineering?

I want them to know that the skills I learned in elementary school still help me in my work today. I remember learning how to break a big task into steps when I was in second or third grade. Our teacher asked us to imagine that we were helping someone who had never made a peanut butter and jelly sandwich before. Instead of saying, “Just put on peanut butter, then put on jelly and there’s your sandwich,” we had to think deeper. I remember thinking, “Well that means first you need to get your bread, then you need to place one side here, and the other side there…” and giving really thorough instructions through to the end. Even now when I give instructions to someone at work, I remember to give them like I would to someone who’s never done the task before.

I would want students to know that it is really powerful to have women in STEM (Science, Technology, Engineering, and Math) fields. It shows that women can pursue any field they want to and accomplish anything they put their minds to.