Gabriel Rodriguez

How did you get to where you are today? What was your training or education?

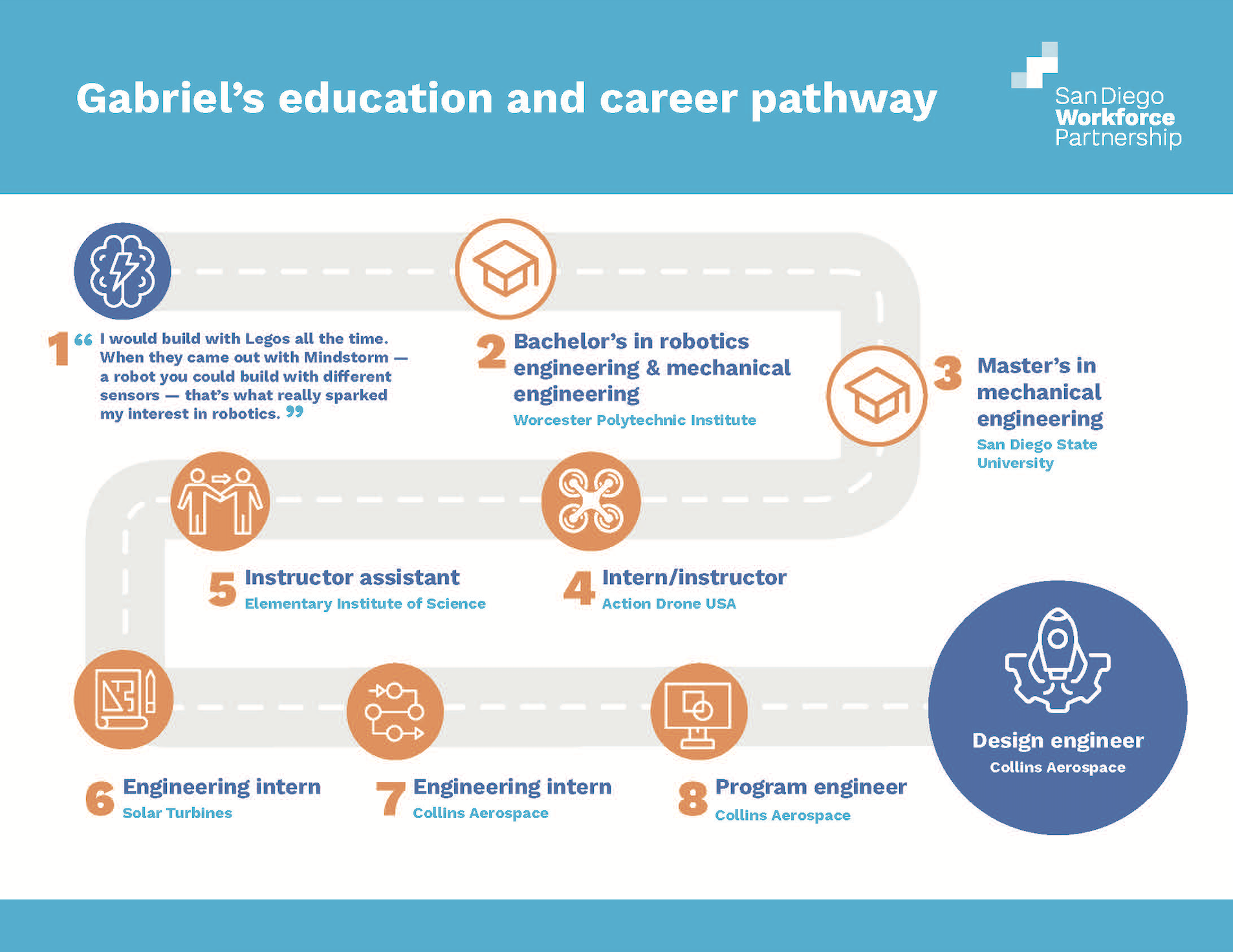

I always tell people that Legos were my bread and butter growing up and I don’t know where I would be without Legos. When I was really young, my passion for engineering started by playing with Lego bricks. After school, as far back as I can remember, I loved coming home and playing with my Legos. I remember when Lego came out with Mindstorm, which let you create your own robot with different sensors, it really sparked my interest in robotics and the power it can have.

When I was in middle school, my older sister joined the robotics program at her high school. She had a robotics competition and told me, “You should come, I think you would like it.” So, I went with her. I ended up liking it so much that I stayed the whole day to see her team go all the way to the semifinals and the finals. Seeing how much I liked it, the robotics teacher invited me to be part of their team. I started to hang out with them and helped them with things they needed.

When I got to high school, I continued my involvement with robotics. I was the robotics team president from freshman through senior year. Robotics was my way to push the envelope because it combined three different aspects: computer science, computer engineering and mechanical engineering. I knew I wanted to go into a field that combines those three disciplines.

When I got to college, it was really cool that my university was one of the few that had a specific degree in robotics. I ended up graduating with a double degree in mechanical engineering and robotics engineering. After that, I knew I wanted to work on the design side so I think it’s pretty cool that my work now is designing plane parts. It comes full circle: I still feel like I’m designing Legos, but just big Legos instead of little ones.

Describe your job.

My role is a design engineer for airplanes. My company works on both commercial and military planes, but I focus on the commercial side. Specifically, I work on a part called the nacelle which goes around the engine of a plane. If you’ve flown in an airplane, you’ve heard and felt the nacelle’s thrust reversers working as you land. Right when you touch down on the runway, you can hear a loud rush of air. That’s the engine spooling up, or spinning faster, and the nacelle’s thrust reversers opening up and forcing air to go through the turbines forward instead of backwards, to help the brakes to stop the plane.

When I work on the nacelle, my job is both making sure the customer is getting what they want and making sure we are designing and selling the part as efficiently as possible. On a day-to-day basis, I look at different parts of the aircraft to see how we can make them more efficient. I explore the existing design of the current parts to see how to improve them, implement the changes and then get the new parts released. I also make sure I “zoom out” and consider the entire aircraft, rather than focusing on my one part. It’s important to make sure that we’re always making the aircraft lighter, more efficient and more sustainable as a whole. I achieve this by looking at different areas on the parts we design to see how we can cut weight or reduce drag. Ultimately, our goal is to make the part we design better so the aircrafts are more cost efficient, safer and more sustainable. This allows more people to fly on the aircrafts and connect people from around the world.

What are the most important skills you use in your work?

One of the most important skills I use is visualization. It is important to be able to visualize the nacelle, where all its parts are, and how all the parts are supposed to work. If I can visualize well, then when something goes wrong, I can open the CAD (Computer Aided Design) model on my computer and easily locate the exact part I’m looking for. It’s not only important to visualize the nacelle for ourselves, but also to communicate with our customers and colleagues so that everyone can understand the changes we are proposing.

What do you love most about your job?

What I love the most is being able to visually see what I’m making and the impact it has on millions of people. From the time I was little, I’ve wanted to design something that we all use and a plane is something a lot of us can’t live without anymore. It’s really cool knowing my work helps people reunite and takes other people to remote areas to serve others. It’s also cool that, when I fly, I sit on the plane knowing I have a small little impact on this flight.

What is something you find challenging about your job?

Sometimes I know a certain part is not working as well as it could be but I don’t know what the problem is. To figure out the problem, I have to do what is called a root cause analysis. Some of the problems I look for have hundreds of variables that make it very hard to find the root cause, so I have to work very diligently to make sure I don’t skip one. The same can be said when designing a part for an airplane. I have to take all the different variables that will affect how this part performs into consideration. This is where modeling software and testing help make planes as safe as they are. I end up using a lot of creative problem solving to tackle the different challenges that come up.

What advice do you have for students thinking about working in engineering?

I think what really sets anyone apart is hard work. I remember going to university and being really worried that other students knew more than me. I thought I wasn’t going to be able to make it. What I learned is that, with hard work, you can really reach any goal or aspiration you have. At the end of the day, whoever wants it more is the one that’s going to get what they want. Put in 110% and I think you’ll be perfectly fine in whatever aspect of life you get into.